~~* A Tour of the Weaving Process *~~

Mohair, the Diamond Fiber

That's the phrase that the Mohair Council of America utilizes to promote the fiber of the angora goat that it markets. It's a great catch phrase and I believe appropriately describes some of the virtues of my favorite of animal fibers. Absolutely glistening when light shines on it (because it such a smooth fiber), it is silky in texture and strong. (It is said that strand for strand it is stronger than steel!)

For some time I've been talking about a large mohair bedspread I was weaving from hand spun mohair yarns. I finally completed it and here is the story of the weaving in pictures.

Though it has been said that hand spun mohair makes for a frail warp and that mohair is best mixed with another fiber, I have found that 100% mohair makes a fine warp. After double plying my warps (NEVER, but never, use a single ply mohair yarn for a warp!) I utilize corn starch in water as sizing to smooth out and add strength to those warp yarns. The sizing tames those hairs that want to fray as they move against heddles in the loom. It works amazingly well.

This project, a king size bedspread sent to Hong Kong, began innocuously that day I received my client, Ms. Jennifer Moyer's, first email. She asked if I would weave a king size bedspread from ivory colored mohair. She'd once slept under a mohair bedspread when on a trip to Morocco and wanted one ever since.

Could I do it? The task seemed monumental to me at first. It would be a bedspread measuring 10' x 10' and woven entirely from hand spun yarns. Formidable task? The shear volume of mohair determined that. A challenge, and one I was willing to take? It would stretch the limits of our creativity and tools. It would be a hall mark event for us. We excitedly accepted the project, so she placed the order that day.

The following is a compilation of pictures that show from beginning to end the sequence of events that transpired to make her dream come true. It is said that pictures say a thousand words.

I hope these images show you the beauty of my favorite animal fiber - mohair, The Diamond Fiber. Be sure to check out BSN's website to see these photos in authentic color.

Graded, Washed and Carded Mohair

From the Field to our Cottage

The first of several mounds of carded mohair prepared by Stanley. A special blend of olive oil and soy bean lecithin is added to very hot water. Then a mist of the solution is sprayed on the picked mohair locks. This acts as a natural 'hair conditioner' and prevents the carding machine from damaging the squeaky clean fleece as it is carded into heavenly cloud like mohair batts. Approximately 20 pounds of mohair was washed, picked and carded for this project.

Mohair Batts Prepared for Spinning

Mounds of Mohair

It is important to note that our cottage industry has already invested quite an expense of time and energy into the mohair that's been prepared. First it takes months of careful shepherding to keep the herd fed and in good health. It is a major task and process in itself since angora goats are the most delicate of domestic livestock species. When shearing begins, days of back breaking work ensue.

Still, there is great satisfaction in this work. The skill and knowledge of preparing the fiber as we do is all but a lost art in itself. One that has been hard won for us and that we are still learning.

Mounds of Skeins

We estimate that approximately 5 miles of home spun yarns were processed by Alexandra for the warp and weft of this project. It seemed like a daunting task but with patience and focused attention it was accomplished.

Repetitive stress was a serious issue that required special care for this art piece. The mounds of soft mohair required weeks of spinning during which time Alexandra often suffered a debilitating episodes of numbness in here arms.

The challenge of the project was not only physical. It requires a tremendous amount of discipline to prevent the more tedious aspects of the yarn preparations from discouraging artistic inspiration. Consistent quality in strength, texture and

More Mounds of Skeins :)

Once the yarns are spun up they are located on the spinning wheel yarn spools. The spools are placed on a holding device called a "lazy kate". The lazy kate suspends up to several spools at a time for the purpose of unraveling the spools in sync to form the double ply the yarns of the warp. Now the spinning wheel spools are filled with double ply yarns that are formed into three foot diameter skeins of mohair.

The Umbrella Swift

The next step in our preparations is to calculate the length of the warp and how many warp threads per inch the item will contain. There are standard mathematical formulas that are applied at this stage. But in the end it is the skill and eye of the artist, her ability to judge the character of the fiber and its yarn, that determines the final length of the warp threads.

Once we have determined the above the skeins are placed in an umbrella swift or similar device so the yarns are reeled off in an orderly fashion.

The Warping Board

The "warping board" is a simple but very effective tool for ordering the length, number and sequence of the warp threads. It is by this means that strand by strand of the warp is measured out and placed in such a fashion so as to prevent the warping work from turning into an awful can of worms. Each strand is placed and counted carefully on the warping board. When plaids or complicated patterns are designed into the woven item this phase of production becomes even more crucial. It is here that the initial pattern is set in the warp.

This photo shows mohair yarn (double ply) on the warping board for the first section of the weaving, the 5' x 10' middle panel of the bedspread. I have only just begun to place yarn onto the board.

The Warping Chains

As the warp yarn fills the warping board it is carefully ties at a nexus of the threads and bundled into a warping chain. These are set aside until the entire warp has been measured and cut.

Another set of chains for the warp

The next aspect of weaving is placing the warp on the loom. We determined to use a simple basket weave pattern for this project which requires a loom with at least 4 harnesses. Harnesses are those elements of the loom that hold the heddles in place. A myriad of heddles are employed in these projects. Each one holds a strand of warp.

The warping chains are tied to the loom. He strand of the warp is sleyed through the heddles in a predetermined pattern. It is here that one can easily cross thread a warp strand which causes considerable headache and redoing. There are various techniques to deal with such a problem but none are as appealing as doing the job correctly to start with. It requires considerable patience and focus of attention.

The warped 60 inch floor loom

Here you can see the warp crossing over the back beam, down onto the rear warp beam. Much care is taken to not cross thread and to apply even tension over the entire expanse of the warp as it is being wrapped onto the warp beam. If this is not properly done the weave will appear uneven and chaotic. In this image there is no tension on the warp and hence its loose appearance

Weaving the Weft

Now we are ready to begin the actual weaving. In this particular case the weft was a special single ply mohair yarn. It also required considerable work since it is mainly spun directly from washed mohair fleece. This technique of spinning is called "tail spun". A very long expensive staple is required. It allows for the end tendrils of the mohair locks to protrude from the yarn for a fantastic ethereal appearance and exceptional loft in the garment. it adds considerably to the character and softness of the final product.

Tail Spun Yarn Weft

Here is a close up of the Tail Spun weft. At this juncture it is often advisable to add long tendrils of mohair lock into the weft. This method is used to even out the texture of the item.

The Side Panels

This photo shows one of the side panels of the bed spread in the process of being woven. On a project of this size, when the weaving spans an extra long period of time, the concern is to make sure you continue the rhythm and character of the weave. You shouldn't be in an angry or complacent mind set. Consistency can't be achieved if you are slamming the breast beam one day and gently the next.

The Side Panels

I was so glad to come to this point in the project. The main panel in the bedspread was 5' x 10' feet and done. I had completed weaving the second panel. This, the third and last (like the second) was woven 2 1/2' x 10' feet. Soon I would be joining all three panels together.

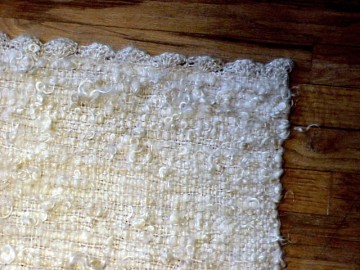

The End, Side and Seam Trim

We opted to finish the trim and seams with a crocheted mohair scallop.

The Seam Gimp

This digitally manipulated image sharpens the seam gimp for easy viewing.

The Border Treatment

This picture shows how the crocheted border was attached to the weaving. Before cutting the warp fringes, the weaving had to be reinforced with zig zag stitching done on a sewing machine. The zig zag is a necessary step to assure that the edges of the bedspread remain strong. The zig zag also keeps the warp in place. Note how very lacy and delicate this edge looks. The crocheted border seemed a perfect way to finish the bedspread.

Another view of the warp end treatment

Classically a woven piece has tassels on the warp ends. This is the preferred and ultimately the strongest method of finishing a product. In this case such a finish would never have served the clients purpose.

The Piece in Its Place

Soft, warm, plush - with the lasting beauty of mohair, an elegant solution to our clients desires. Note in the background the city lights of Hong Kong with the Bank of China in view. My customer says that there is a zoo between her apartment and the bank building. Sometimes she can hear the chatter of monkeys from down below. Thank you David V Bartlett for the images from Hong Kong

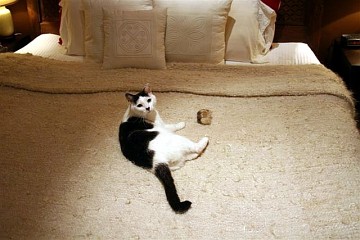

Horton Enjoying the New Luxury

This is Horton, a very important member of the family. He is shown here with his toy sheep. Note the texture of the woven bedspread. I purposed to allow the tail spun "tendrils" of mohair to escape the weave of the bedspread (per my customer's request.) She wanted plenty of "texture" and plenty of mohair loft!

Where It All Begins

This little creature doesn't have to do anything but be what it is in order to fulfill its purpose here at Singing Falls. Were happy to have it that way. We hope you have enjoyed this pictorial presentation and that you have found it inspiring.

Top Click for the gallery